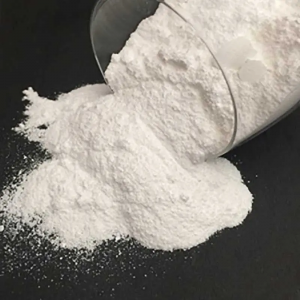

Sodium carbonate, commonly known as soda ash, is a versatile compound with a variety of uses across multiple industries. It comes in two main forms: light soda ash and heavy soda ash. Understanding the differences between these two types of soda ash is essential to choosing the right product for a specific application.

Light Soda Ash is characterized by its low bulk density and fine particle size. This form of sodium carbonate is often preferred in applications where rapid dissolution is required. It is widely used in the glassmaking industry, where it acts as a flux to lower the melting point of silica, thereby facilitating the production of glass. In addition, light soda ash is used in the production of detergents, where its ability to soften water improves cleaning efficiency. Its fine particles also make it suitable for use in chemical processes that require precise measurement and rapid dissolution.

Dense soda ash on the other hand, has a higher bulk density and larger particle size, making it ideal for applications that require a more stable, less dusty product. This form is often used in the manufacture of glass, ceramics, and water treatment. Its density makes it easier to handle and transport, making it a preferred choice in large-scale industrial applications. Additionally, dense soda ash is often used to produce sodium bicarbonate, which has a variety of uses, including baking and as a leavening agent.

In summary, both light and heavy soda ash play an important role in a variety of industries. Understanding their unique properties and applications allows manufacturers and consumers to make informed decisions to ensure the best results in their respective processes. Whether it is glass production, detergent formulation or water treatment, the choice between these two types of sodium carbonate can significantly affect efficiency and effectiveness.

Post time: Mar-01-2025